Have you ever thrown a paper airplane? How did it fly? Paper airplanes vary widely in design, and those differences lead to meaningful differences in the way that they fly. Some airplanes fly quickly through the air, while others glide slowly. Sometimes, a paper airplane will tip its nose upward, leading to a stall. Why do these things happen?

The mechanics of paper airplanes are interesting because they are similar to those of most things that move quickly through the air. They have four basic forces acting on them:

via auntannie.com

The thrust comes from you when you throw the plane. Thus, the plane has no thrust in flight. The reason it doesn’t continue to slow down during flight is because it is also falling, “converting” its potential energy into thrust as it falls.

The lift comes from the difference in air pressure above and below the wing. This is caused by the shape of the wing, known as an airfoil. Lift is proportional to the size of the wing and the square of the speed of the plane.

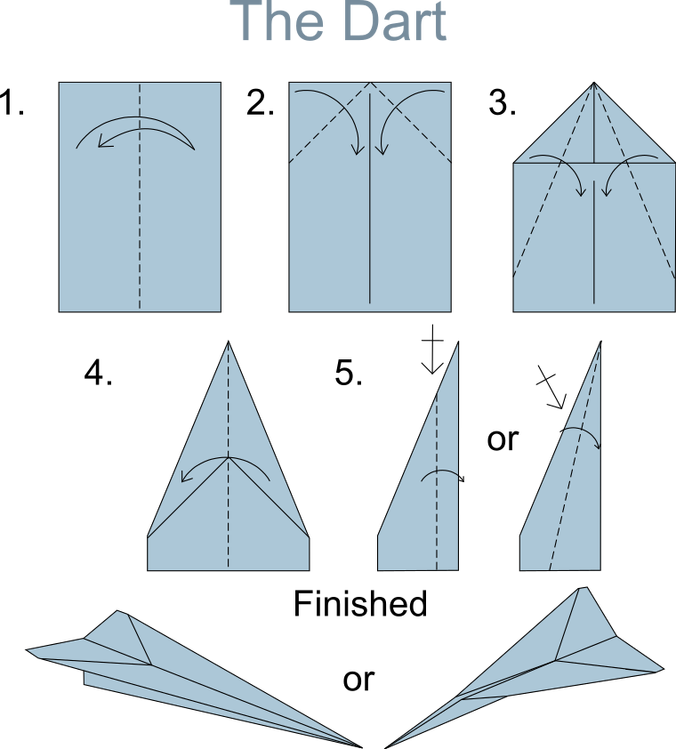

So how do these forces affect how a plane flies? Take for example the standard paper “dart” plane:

via Wikigami

If you have flown this plane before, you know that it flies quickly, but drops to the ground relatively quickly. This can be explained as the plane having little drag, but little lift as well. More specifically, the lift and gravity forces are not perfectly aligned like they are in the first image. Rather, the center of gravity is slightly ahead of the center of lift in this plane, causing it to tip downwards and fly towards the ground.

Another popular plane is this “glider”:

via Instructables

This plane has a slow and steady flight if thrown gently or even dropped from a high place. Even without thrust from the person who throws it, it is able to maintain steady flight, if at the cost of a slight drop at the beginning. This indicates that its gravity and lift forces are aligned correctly. While it does not fly as fast, it has a larger wing surface area, which allows it to get enough lift at lower speeds.

With these ideas in mind, it’s easy to pick the correct airplane for any task. (That’s a common issue people have… right?) I once participated in a paper airplane competition based on longest total flight time. Knowing this, I instantly started folding large-winged gliders. When my plane nosedived too often, I folded it to place less paper in the front half, which moved the center of mass further back to compensate for the nosediving, which led to a steady-flying glider.

I went on to win $20 in that small competition. While, in real life, paper airplanes competitions are few and far between, this knowledge is not useful exclusively in these rare situations. Just to understand the basic mechanics at work in the planes, drones, and squirrel suits of the world is enlightening.