3D printing is a fad that swept the “maker movement” to encourage young designers to create just about anything they can model. Using standard CAD (or Computer-Aided Drafting) programs, just about anybody can print their own nick knack for enjoyment or small projects. So what exactly is 3D Printing? According to 3DPrinting. com:

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

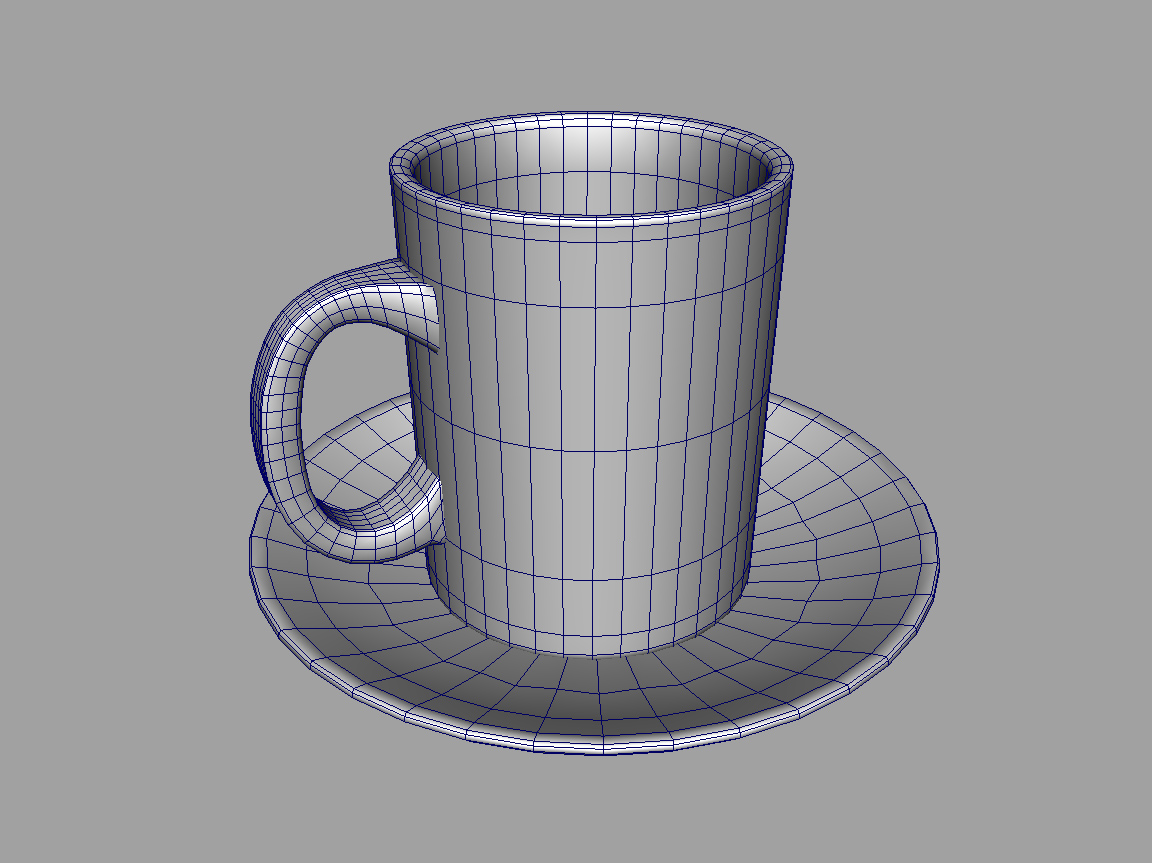

Essentially, a 3D printer can read a file (typically .stl) like this one:

and “print” it to the physical object by heating plastic (or whatever material) and super-cooling it as it moves around the model. It’s a relatively simple process, but the machinery and programming it takes to assemble and construct one of these is not so simple.

As far as expensive-wise, it really depends on what your printer needs to do. At home appliances can be as low as $200, but these only print objects up to a 200 mm cube. For a bigger duty printer, such as the ones used at large manufacturing plants to print metal parts and the like. (These can be larger than a person!) Unfortunately, as is with most technology, the price increases dramatically– up to and above $10,000. 3D Printing.com has a great filter and search to find exactly the printer that’s right for whatever job.

But what does 3D printing have to do with the business world? Well, more so for researching companies, 3D printers offer a quick, foolproof machining process for small or large parts. There’s no lost time to explain to a machinist exactly what to create from the drawing of an engineer; instead, the computer has exactly the code of what to create. In prototyping, this is extremely helpful for meeting time frames.

I mentioned there’s no communication with a machinist above, so on that same note, advanced 3D printers are making another job opportunities less available. Just as the progression of CAD gave the job of draftsman to engineers, 3D printers are taking up that role again. Although that does decrease costs for companies–and machining is not a hot-button career–people are finding it more difficult to learn the basics of machining by hand.

These pros and cons are discussed further in the Green Garage‘s article about improving 3D printing technology.

Although plastic is the definitive top usage for 3D printers, it’s not the only material being used. One application being researched, especially in light of the large number of patients on the organ donation waiting list, is printing organs and other tissues. In a special machine, mulitple nozzles deposit “bioink” as it has been coined of organ-specific, blood vessels, muscle tissue, etc to create an inorganically made organic organ. (How’s that for a tongue twister?) According to C. Lee Ventola’s article about this topic, he says, “Although tissue and organ bioprinting is still in its infancy, many studies have provided proof of concept. Researchers have used 3D printers to create a knee meniscus, heart valve, spinal disk, other types of cartilage and bone, and an artificial ear.” Now this article was also published in 2014, so much more has been accomplished since then.

So why are people against 3D printing? First of all, the question of how this effects the environment is very important. 3D printers can use up to 50 to 100 times more electrical power than the most common alternative method, according to MIT’s Environmentally Benign Manufacturing. Although one or two uses for a highly complex part in prototyping is not difficult, large scale manufacturing may be off the table. On top of that, the reliance on plastics is very concerning. Excess plastic is non-biodegradable, and with the movement to clean up landfills, 3D printing may not be the way.

So what do you think? Is 3D printing the way of the future for manufacturing? Or is it a fad to be used in classrooms or researching firms?