While the plumbing in a rocket engine is seen as very complex (which it is), its premise is relatively simple, accelerating gasses down through a nozzle to produce thrust. In general, there are two main types of engines, solid rocket motors and liquid fuel engines. Solid fuel engines are all made in the same general way other than size. There are four major design philosophies around liquid fuel engines, open cycle, closed cycle, full flow, and cold gas. Each engine type has its own advantages and disadvantages.

Firstly, solid rocket motors use a solid fuel usually made from a slow, but fiercely burning material mixed with an oxidizing agent. Next, the solid fuel is packed into a high strength aluminum tank with ablative thermal insulation, that is material designed to decompose when exposed to heat that creates an evaporative cooling effect. Then, a channel is molded in the center of the tank from its base to where the nozzle sits or attaches (based on manufacturer) where the ignition system is located. Usually, the ignition system is an electronically activated detonator that starts a controlled burn of highly flammable magnesium compounds which chain react with the main fuel.

Solid rocket engines provide many advantages. Primarily, they are much cheaper to produce and can provide an obscene amount of thrust for a decent amount of time. Additionally, they are simpler to manufacture compared to their liquid fueled brethren. However, there are some disadvantages to this type of engine, mostly revolving

around a lack of control. These engines once started cannot be shut down until the fuel is depleted, this can be a safety hazard for crewed vehicles. The most famous example is during the Space Shuttle Era, where if a catastrophic problem occurred; the vehicle would have to detach itself from the center tank at a specific altitude to ‘glide’ to the runway. Another disadvantage is the lack of significant thrust gimballing, meaning the ability to change the orientation of the engine bell to vector thrust in a specific direction. All in all, solid rocket motors are most useful as additional booster stages for the main launch stage. For example, the Atlas rockets can hold up to eight solid rocket motors to create more thrust on launch and have the potential to kick the spacecraft into a higher orbit.

around a lack of control. These engines once started cannot be shut down until the fuel is depleted, this can be a safety hazard for crewed vehicles. The most famous example is during the Space Shuttle Era, where if a catastrophic problem occurred; the vehicle would have to detach itself from the center tank at a specific altitude to ‘glide’ to the runway. Another disadvantage is the lack of significant thrust gimballing, meaning the ability to change the orientation of the engine bell to vector thrust in a specific direction. All in all, solid rocket motors are most useful as additional booster stages for the main launch stage. For example, the Atlas rockets can hold up to eight solid rocket motors to create more thrust on launch and have the potential to kick the spacecraft into a higher orbit.

While solid motors are the cheapest the most common engines are liquid fueled engines. They come in many flavors, Gas generator cycle (open cycle), closed cycle, full flow, and cold gas/monopropellant. The first type of liquid fueled engine to be used on an orbital rocket was a gas generator cycle (open cycle) engine. All liquid fueled engines (other than cold gas thrusters) require a pre-burner to power the turbo pumps that allow for the fuel to enter the combustion chamber at a high enough velocity. A simple way to think of  a pre-burner as a mini rocket engine that points toward a turbine, the fuel to oxidizer ratio in the pre-burner is not perfect and can (depending on the fuel) create a black sooty substance that clogs and sticks to everything, which becomes problematic when trying to reuse the pre-burner exhaust making it impossible, so it is dumped overboard. All open cycle engines use carbon derived fuels such as RP-1 or cryogenic kerosene.

a pre-burner as a mini rocket engine that points toward a turbine, the fuel to oxidizer ratio in the pre-burner is not perfect and can (depending on the fuel) create a black sooty substance that clogs and sticks to everything, which becomes problematic when trying to reuse the pre-burner exhaust making it impossible, so it is dumped overboard. All open cycle engines use carbon derived fuels such as RP-1 or cryogenic kerosene.

These engines are relatively cheap for a liquid fueled engine and can produce large amounts of thrust. In fact the F-1 engines aboard the Saturn V moon rocket were open cycle. But there are some serious downsides to consider for this engine. They are very inefficient since some fuel is wasted during the pre-burner stage. Also, they are notoriously hard to start since the pre-burner requires fuel flow and oxidizer, but the fuel and oxidizer pumps also require the turbo pump to function.

Other than open cycle engines, closed cycle engines are different due to the way fuel and oxidizer enter the pre-burner and power the turbo pump. Essentially, the fuel and oxidizer can enter the pre-burner in two different ways, either fuel rich or oxidizer rich, both function in the same way by redirecting the fuel or oxidizer rich exhaust gases into the main combustion chamber, whether or not they are fuel/oxidizer rich

depends on the type of fuel used, for example Hydrogen and oxygen are typically used in fuel rich closed cycle systems t the low density of hydrogen causing less of a need for a larger oxidizer tank, thus reducing the overall weight of the fuel tank. A prime example of a closed cycle system is the legendary Aerojet Rocketdyne RS-25 or the space shuttle main engine.

The main advantage of this system is the amount of thrust that they can produce. Additionally, they are very efficient regardless of altitude while being some of the most reliable engines on the market. However, this performance comes at a cost, these engines are incredibly expensive and relatively complex and heavy.

The final category of engine derives from a closed cycle system and is called the Full flow system (staged combustion cycle). For a long time, it was once thought that this type of engine was impossible due to the materials needed to survive the extreme chamber pressures and temperatures. Recently SpaceX has finally developed the materials for such an engine. Their new Raptor engine is the next generation of propulsion using an exotic methane/oxygen fuel. This engine works by essentially giving each pump for fuel and oxidizer its own turbopump that powers one component either fuel or oxidizer pumps. The fuel side is oxidizer rich and the oxidizer side is fuel rich to create an even burn ratio, the fuel and oxidizer rich turbopump exhaust is funneled directly into the combustion chamber. This design can produce more thrust than the RS-25 at a much smaller size while maintaining the high efficiency and even being cheaper than it. However, the Raptor has yet to be tested in space yet. It has been used in the latest Starship tests and has so far proven itself in terms of reliability, practicality, and feasibility as a first stage engine.

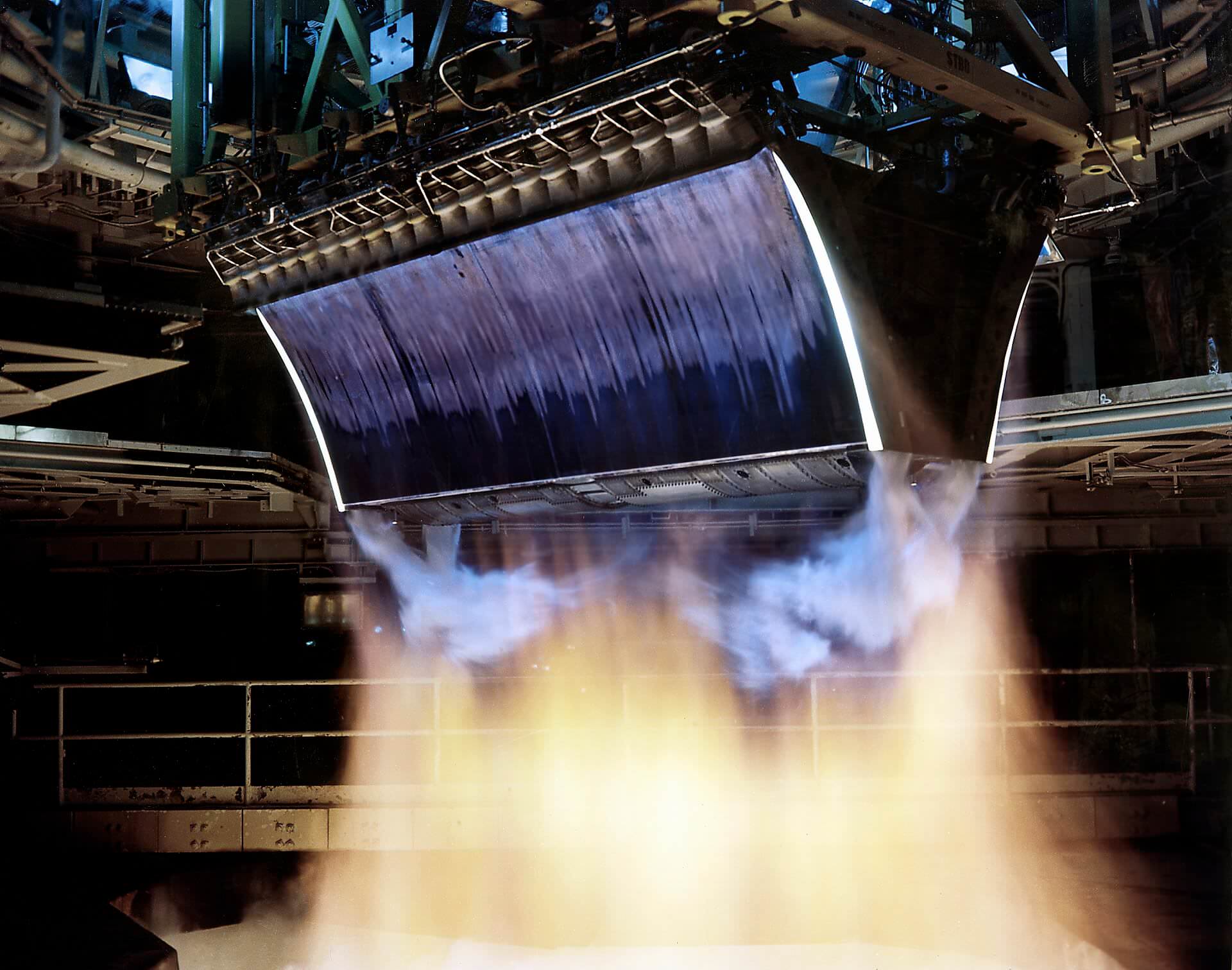

This comes at a cost for fuel efficiency, The shuttle’s main engines sucked through over 170 pounds of fuel every second. The aerospike engine avoids the fuel efficiency problem through a unique engine bell shape. The tapered wedge shape allows exhaust gasses to be focused down the sides of the slopes of the engine bell. This allows for the exhaust to stay laminar at extremely high altitudes without a significant loss in thrust and fuel efficiency as they are 20% to 30% more efficient.

This comes at a cost for fuel efficiency, The shuttle’s main engines sucked through over 170 pounds of fuel every second. The aerospike engine avoids the fuel efficiency problem through a unique engine bell shape. The tapered wedge shape allows exhaust gasses to be focused down the sides of the slopes of the engine bell. This allows for the exhaust to stay laminar at extremely high altitudes without a significant loss in thrust and fuel efficiency as they are 20% to 30% more efficient.