In the aerospace industry, there is a mythical type of propulsion that can create obscene amounts of thrust for the same amount of total fuel burned. These are called Aerospike engines. These differ from a traditional engine due to the lack of a singular engine bell, instead there is a central wedge or conical piece of metal, usually titanium or carbon infused tungsten. This unorthodox design is to solve the main source of inefficiency of De Levalle style engine bells.

As a spacecraft accelerates upward, the surrounding air pressure keeps the hypersonic exhaust from the engine laminar, allowing for the greatest amount of transfer of kinetic energy to the rocket. As altitude increases, the ambient air pressure decreases when this occurs, the exhaust gasses expand outward, thus losing efficiency. The outward expansion of exhaust is an aerospace engineer’s boogeyman. Aerospike engines solve this through engine bell geometry. The shape of the engine bell and ambient air pressure are the two main determinants for thrust efficiency.

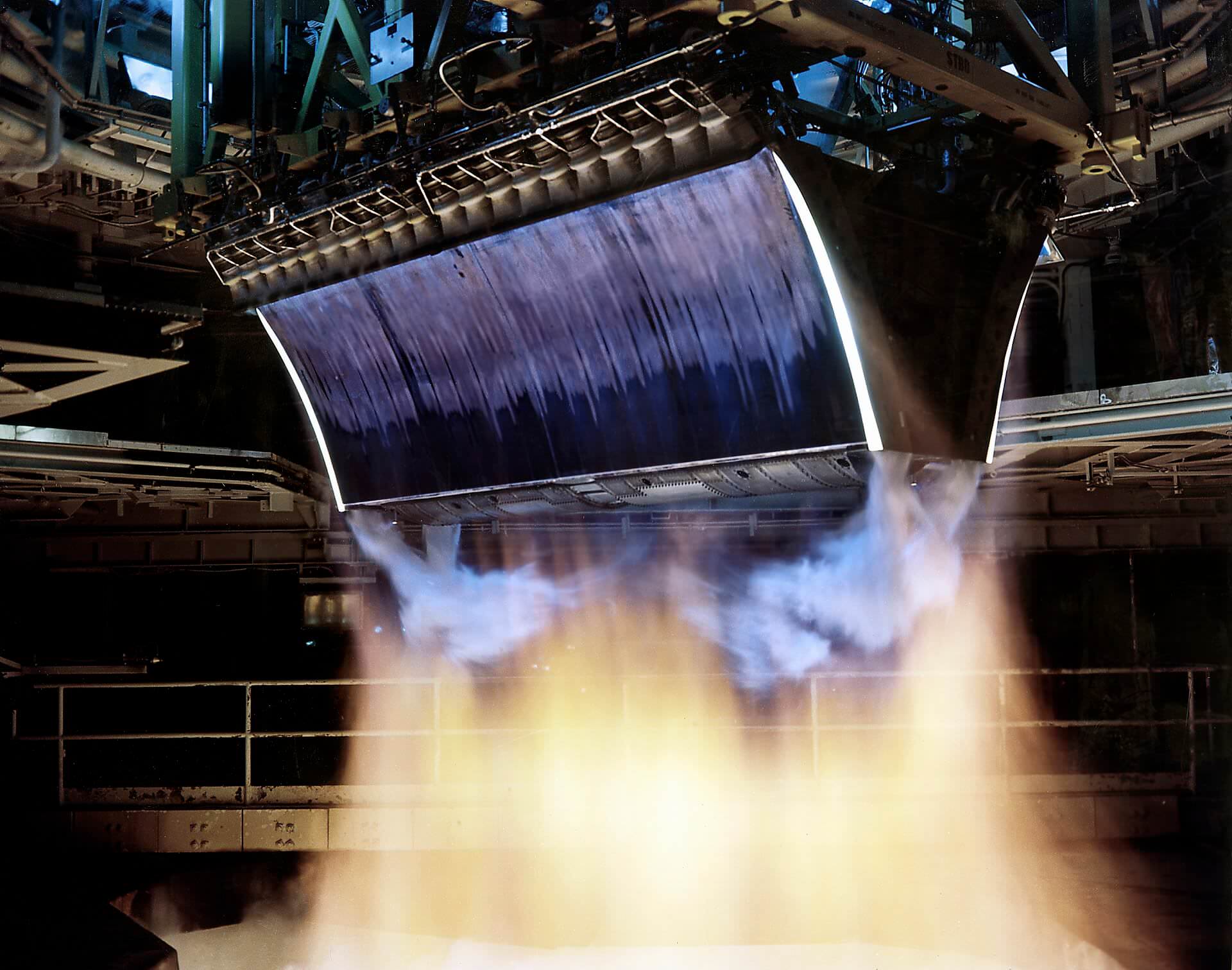

Keeping the exhaust gasses as laminar as possible for as long as possible can be done in two ways, altering the geometry of the engine bell or the velocity of the fuel and oxidizer mix in the engine’s injector plate and turbo pump assembly. For example, the space shuttle’s Aerojet Rocketdyne RS-25 main engines overcame this problem through sheer power, its exhaust velocity was well over Mach 4 which allows it to not experience the thrust loss through altitude. This comes at a cost for fuel efficiency, The shuttle’s main engines sucked through over 170 pounds of fuel every second. The aerospike engine avoids the fuel efficiency problem through a unique engine bell shape. The tapered wedge shape allows exhaust gasses to be focused down the sides of the slopes of the engine bell. This allows for the exhaust to stay laminar at extremely high altitudes without a significant loss in thrust and fuel efficiency as they are 20% to 30% more efficient.

This comes at a cost for fuel efficiency, The shuttle’s main engines sucked through over 170 pounds of fuel every second. The aerospike engine avoids the fuel efficiency problem through a unique engine bell shape. The tapered wedge shape allows exhaust gasses to be focused down the sides of the slopes of the engine bell. This allows for the exhaust to stay laminar at extremely high altitudes without a significant loss in thrust and fuel efficiency as they are 20% to 30% more efficient.

This solution seems like the obvious from an engineering standpoint, but it has a significant number of drawbacks that make these engines extremely impractical. The most poignant issue is one of cooling. In propulsion waste heat can be done in two different ways, passively and actively. A primary example of passive cooling of a rocket engine is seen in ULA’s Delta IV heavy. The RS-68 main engines are lined with a graphite/silica mesh. This mesh is designed to disintegrate mid flight or ablate. The ablative material is designed to take the heat away with the shards that are discarded. This is the cheapest way of cooling an engine, but also unsustainable for repeated use. The second method is active cooling. This is done by running the cryogenic oxidizer through coolant pipes inside the engine bell itself. For example, the previously mentioned RS-25 uses the same system. The only problem is that this method is extremely expensive. The aerospike engines that are currently being tested have active and passive cooling measures in place, but it is still not enough to cool the mammoth engine.

Other than overheating issues, Aerospike engines are extremely complicated pieces of hardware, even compared to traditional engines. The exhaust cones themselves take hundreds of hours of careful machining and along with the added plumbing need to feed the 20 individual combustion chambers and additional calibration of each individual nozzle. This is since this design is relatively new and never done under a large production scale.

The added complexity also plays into the engine’s weight, these engines are extremely heavy weighing in at 1400kg per engine. The weight is where this engine loses its advantages, the fuel efficiency is negated due to the increased weight, and since they are so expensive most rockets would have better performance using a traditional style of engine.

Conclusively speaking, aerospike engines need to overcome the weight, complexity, and heating hurdles to be the next generation of propulsion systems. Aerojet has been making great strides in bringing the cost down and the simplicity higher, but there is still a long way until they are commonplace in the ever-evolving industry.

I really enjoyed your post! I think you did a really nice job of being very detailed throughout. I do think it was a little difficult to comprehend at times, so I think it could be beneficial to specify who your audience is and how to write for them in particular.

As a mechanical engineer who is interested in aerospace applications, I enjoyed reading your blog! However, I would love to see the websites and resources you used, that way I could also read them. Overall, good job!

Wow very interesting post! I know you said in class you were too technical but I really enjoyed reading this because I do not know too much about this topic!

Very interesting! I am not particularly familiar with aerospace vernacular, so some of it went over my head. I know it may be a bit difficult, but try to illustrate points in laymen’s terms and utilize graphics to convey your ideas. Keep up the good work!