Experience

PB Heat LLC (also known as Peerless Boilers) designs and manufactures high efficiency oil and gas boilers for both residential and commercial applications. In summer 2016, I had the opportunity to work as an intern in PB Heat LLC’s engineering department. My main responsibilities included testing boilers, calibrating instruments, drafting technical documents, creating laboratory procedures, and completing hands on projects.

Boiler Technician

The Department of Energy (DOE) requires monthly testing to be performed on most of PB Heat LLC’s products. I was trained by two senior technicians on how to properly assemble, test, and dissemble boilers safely. Assembly included attaching thermocouple sensors, piping, and wiring electrical connections on the boiler. Some tests I performed included CO and CO2 particulate measurements, heat generation timing, and ensuring safety shutoff valves and switches worked when boilers were subjected to extreme conditions.

Technical Drafting and 3D CAD

When I was not working in the lab, I had the opportunity to sharpen my drafting skills. I was assigned dozens of schematics every week to revise. Using AutoCAD LT, I learned how to properly make revisions to electrical and mechanical diagrams. The company was also developing new boiler prototypes during my time there. The engineers working on the prototypes would assign me to create or modify 3D models on Solidworks.

Bypass stand I made

Projects

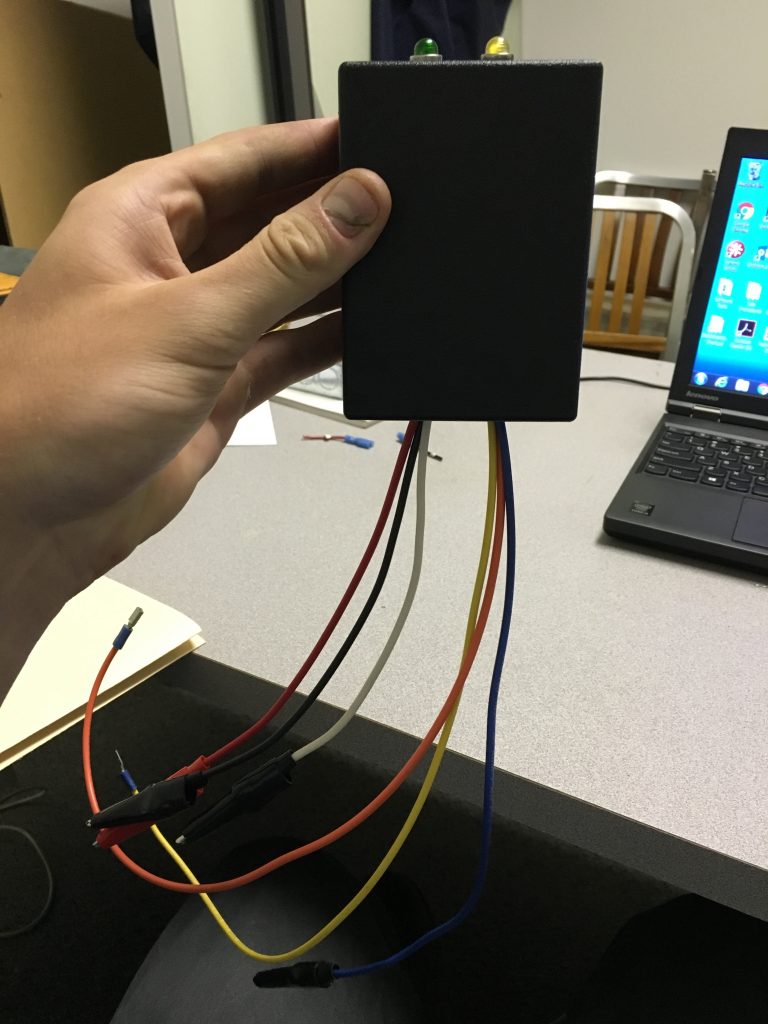

Over the summer I was assigned two main projects. One project was an indicator used to speed up the process on the assembly line. From start to finish I designed and built five ignition indicators while documenting the entire process. Two years later these indicators are still being used. The other project I completed was a bypass stand to use in monthly testing. Given a 3D model of the stand by an engineer I successfully sweated over 50 pieces of pipe together.