Glassblowing and sand casting helped LEAP students ponder the structural properties of two important common materials, glass and aluminum. They weren’t aware of some of the unique properties until they visited the material science labs in the College of Earth and Mineral Science over the last two weeks.

Two material scientists, Jenn Rygel and Jess Serra, took the students through a glass blowing experience that was part science and part art. They watched the smooth choreography between Jenn and Jess as one blew air through a tube and the other shaped the molten glass into a plate, a bowl, and a turtle. They also experienced the breaking of Prince Rupert’s Drops–a tadpole shaped glass made by dripping hot molten glass into cold water that results in large compressive stresses on the exterior. Students discovered the fun of breaking the tail end of one of these drops, because once the stress is released, the drop disintegrates explosively. They also got to make their own colorful glass flowers.

Then it was onto lost foam sand casting. Dr. Amy Robinson met with the group to explain the major alloying elements added to aluminum, such as silicon, magnesium, and copper, and how they alter the properties of aluminum to make it stronger or flow more easily. She gave an overview of the three types of casting methods: graphite mold, green sand casting and lost foam sand casting. Then it was time for art to intersect with science again.

Then it was onto lost foam sand casting. Dr. Amy Robinson met with the group to explain the major alloying elements added to aluminum, such as silicon, magnesium, and copper, and how they alter the properties of aluminum to make it stronger or flow more easily. She gave an overview of the three types of casting methods: graphite mold, green sand casting and lost foam sand casting. Then it was time for art to intersect with science again.

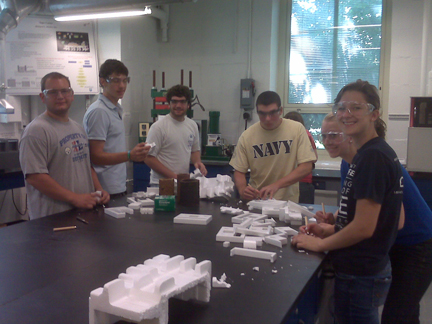

Students used Styrofoam and carving tools to make their own molds. Some made molds of their initials, some chose off-the-wall designs, such as an abstract shape or a Sponge Bob plaque. Once the molds were completed, Dr. Kimmel and Dr. Robinson suited up in their protective garments for the casting. The hot molten aluminum was poured into protective fiber sleeves. A short cooling period followed, and after the “shake out,” the final shapes were revealed. Students then visited the lathe and sandblasting machines to polish their masterpieces! This hands-on experience with processing, structure, properties, and performance of glass and aluminum made students appreciate how much there is to discover about the materials they interact with daily.