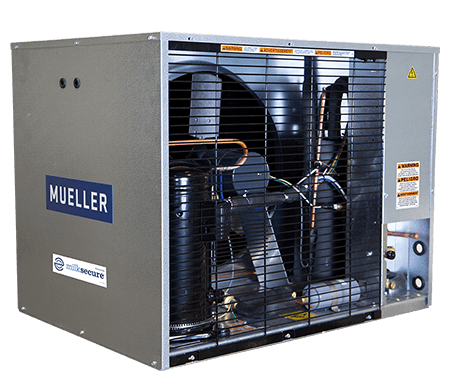

Efficient milk cooling is a critical aspect of dairy farming, directly impacting the quality and safety of the milk produced. Proper cooling not only preserves the freshness of the milk but also prevents bacterial growth. One of the most effective ways to efficient milk cooling is through a rapid cooling system. These systems utilize technology such as plate coolers that quickly reduce the temperature of milk to a safe range. Rapid cooling is essential to stop the growth of bacteria and preserve the quality. Dairy farms are starting to adopt energy-efficient milk cooling equipment. Energy-efficient systems not only reduce operational costs but also contribute to environmental sustainability. Technology like variable speed compressors and electronic controls can make a big difference in power consumption used for milk cooling.

To ensure consistent and efficient milk cooling, regular maintenance of cooling equipment is imperative. Farms should establish a routine maintenance schedule like checking refrigerant levels and inspecting insulation. Additionally, implementing monitoring systems that provide real-time data on cooling temperatures and equipment can help catch problems faster. Investing in refrigeration systems with sufficient capacity is crucial for maintaining the ability to cool milk in the event of an equipment breakdown.

Efficient milk cooling is a fundamental aspect of dairy farm management, directly affecting the quality and safety of the end product. By incorporating rapid cooling systems, ensuring adequate refrigeration capacity, adopting energy-efficient equipment, implementing regular maintenance practices, dairy farms can optimize their milk cooling process.