The objective of this project is to design and simulate a system that captures low-temperature waste heat from a fuel cell and recovers it in the form of usable energy.

Sponsor

Volvo Penta

Team Members

Chinmay Gupta | Jesper Lidqvist | Shreya Manoj | Justus Lindqvist | Deeksha Sharma | Fredrik Özaras | Rosellen Martin | Robert Sugumaran | Hunter DiDomizio | | |

Project Poster

Click on any image to enlarge.

Project Summary

Overview

As climate change and the burning of fossil fuels continues to threaten the future state of our planet, the emergence of clean energy technology, like fuel cells, proves to be a viable source to lessen the impact from the energy sector. However, these clean energy technologies have room for improvement. The goal of this project, sponsored by Volvo Penta, was to design and simulate a system that captures waste heat from a fuel cell and regenerates it into reusable energy. The waste heat recovery system was designed for a commercial vessel, however, future applications include cars and various other modes of transportation.

Objectives

• Identify and analyze the most efficient waste heat recovery systems.

• Develop a feasible and realistic solution concept for recovering waste heat from low-temperature heat dissipated by a fuel cell.

• Provide Simulink models/CAD drawings/physical prototypes for showcasing rated performance.

Approach

• Evaluating potential concepts to maximize customer value. Starting with traditionally successful novel technology.

• Pugh-matrix to understand how each concept will fulfill customer needs.

• Research of applicable parameters and variables that pertain to the chosen system.

• Mathematical analysis of the optimal concept to calculate energy production, efficiency, and design specifications.

• Development of a comprehensive explanation of how the WHR system and its sub-components operate will be developed.

• Following detailed written and mathematical computation of the WHR system’s design, a CAD drawing of the engineered device and a simulated heat flow map will be provided as a visual.

• Identify and analyze the most efficient waste heat recovery systems.

• Develop a feasible and realistic solution concept for recovering waste heat from low-temperature heat dissipated by a fuel cell.

• Provide Simulink models/CAD drawings/physical prototypes for showcasing rated performance.

Outcomes

• Given our goal to evaluate and compare technologies for waste heat recovery, we simulated our final two concepts using Simulink and Comsol.

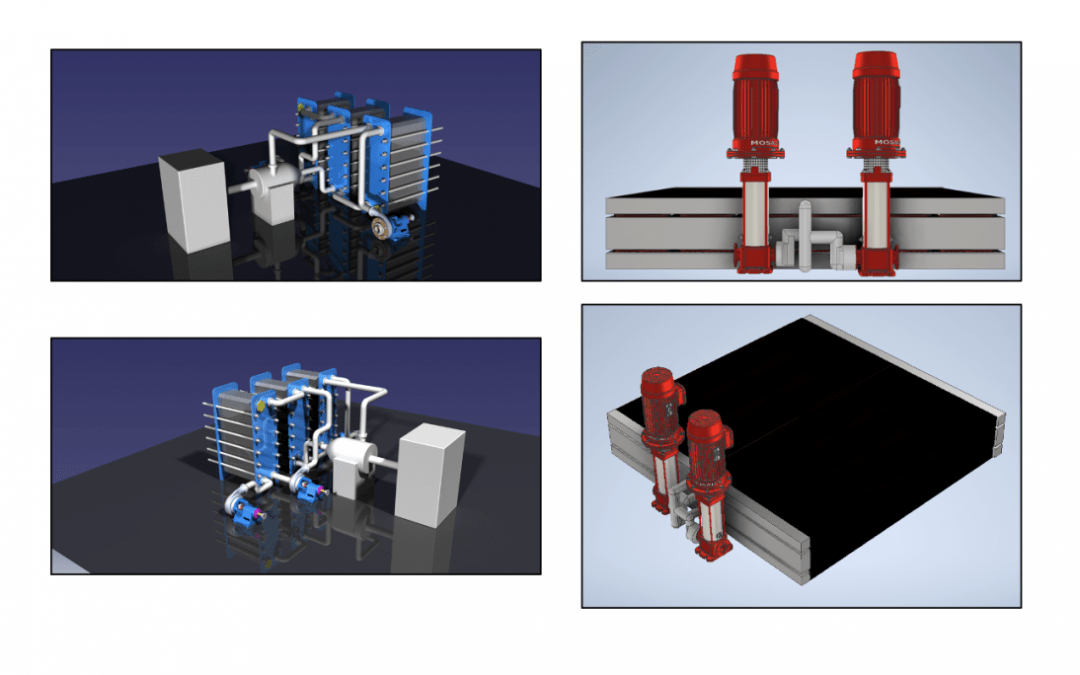

• We also created CAD renders to accompany each of the simulations to better visualize our design

• Our ORC model consists of a heat exchanger, turbine, regenerator, pump, and a water-cooled condenser.

• The top portion of our TEG model consists of a hot side heat reservoir, pump, pump controller, and a heat exchanger; the bottom portion, is a mirror of the top for the cold side, and multiple stacked TEG elements lie sandwiched between the two.

• The ORC model, using Pentane as the working fluid, showed an added efficiency of ~5%, as supported by previous literature, with an output of 25kW. The TEG system showed a power output of 1kW

• The ORC remains more efficient but is bulky and expensive. Comparatively, the TEG system is a novel solution, with fewer moving parts, but has lower efficiency. Both systems have their own advantages with different design contexts.