The object of this project is to evaluate the effect prolonged exposure to Hydrochloric Acid has on the wall thickness of a localized interior portion of 1018 Low Carbon Steel Coiled Tubing.

Sponsor

Schlumberger Limited

Team Members

Lance Marx | Zhantao Zhang | Alexander How | Brock Hinton | Kelsey Jenkins | Clay Moyer | | | | | |

Project Poster

Click on any image to enlarge.

Project Summary

Overview

Schlumberger challenged our capstone team to collect and analyze corrosion data for 1018 low carbon steel to mimic conditions of gas and oil line tubing that is exposed to environmental factors for extended periods of time. The data will be used by Schlumberger to understand the degree to which corrosion compromises the mechanical properties of low carbon steel tubes.

Objectives

– Corrode 24 low carbon 1018 steel tubes in groups of 8 to three different level of

corrosion depth: mild, moderate, and severe.

– Deliver all 24 corroded steel tubes to Schlumberger for fatigue testing

Approach

– Research safe experimental corrosion inducing processes

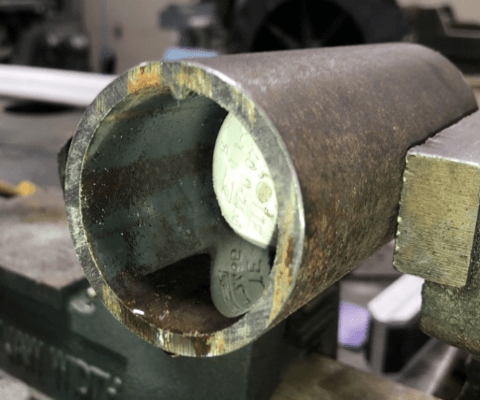

– Determine nondestructive evaluation for depth of corrosion without cutting the tubes

– Research stopper mechanism design and materials to isolate corrosion

– Design a testing rack to support 8 tubes- each 6’ long, 2” in diameter, and 40 lbs

– Induce mild, moderate, and severe levels of corrosion on steel tubes

– Ensure removal of oxidation layer at each step of the corrosion process

– Evaluate the depth of corrosion and level of pitting present by providing ultrasonic

thickness measurements and borescope images for each corroded tube

Outcomes

– Schlumberger will complete fatigue testing of corroded samples to determine the

relationship of mechanical property changes to the level of corrosion.

– Testing procedures and timelines for future corrosion experiment can be modeled after

these experiments as literature has minimal research on purposefully inducing

corrosion to samples for evaluation.

– Ideal testing procedures were developed to optimize corrosion induction to model field

conditions of corroded tubes. A kinetic plateau for corrosion occurs after 4 hours of

acid exposure, regardless of chloride ion concentration present.

– Schlumberger will use the data and conclusions of this project to model future in-

house corrosion testing.