For decades, science fiction in books and movies have captivated audiences worldwide, imagining new worlds and impossible scenarios, and perhaps most interestingly, new technologies. From Star Wars to Back to the Future, our culture has become obsessed with these fantastical stories. We may not have lightsabers to fight our battles, or DeLoreans which can take us back in time, but some technologies from these and other sci fi stories have been developed since their release. That’s the great thing about scientists, if we really want something (especially something nerdy), we’ll do whatever it takes to get it, even developing new materials. Today, let’s rev our engines up to 88 miles an hour and head to a galaxy far, far away. It’s time for the newest edition of Materials Mash-Up.

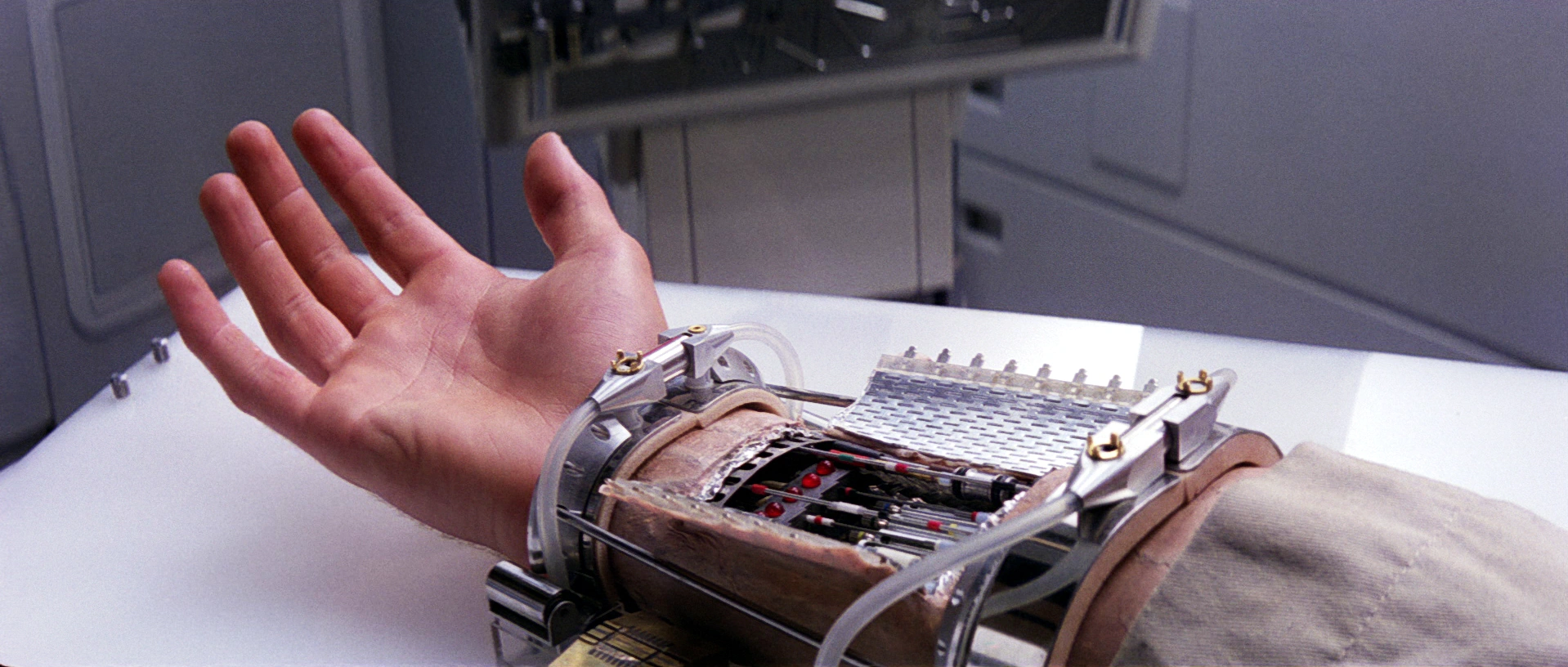

You probably remember the iconic scene from Star Wars in which Darth Vader chops off Luke’s hand with a lightsaber. It’s an intense moment, and later Luke is fitted with a bionic hand, which allows him to carry on with his normal life, fighting the dark side and whatnot. In the time of the release of the Star Wars films, prosthetics’ capabilities were limited, but in the time since then, the field of artificial limbs has improved drastically. The advent of 3D printing allows for extreme personalization of prosthetics, and new technologies can even connect to the brain to control the prosthesis. These models are called “Luke Arms.”

Another SciFi favorite is Back to the Future, which in its second movie traveled to 2015. We recently passed that year, and many fans were excited to see if the technological developments had met the movie’s predictions. One of the most notable inventions from the series was the flying cars, and these are actually in development. The biggest challenge in matching ideas from the movie is VTOL, or Vertical Take Off and Landing. This process requires a 1:1 weight to thrust ratio, so it is very impractical for cars. Engine blocks need to be made with thermodynamically stable materials, which are almost always heavy, and while lightweight materials like aluminum can be used for car frames and exteriors, other materials are needed as well, and the weight requirements make these types of cars simply unsustainable.

As Marty McFly, hero of Back to the Future, is exploring the 2015 town, he sees a holographic shark as a movie advertisement. This was something that seemed truly unreasonable to replicate in the real world. Today, however, we’re much closer to this end goal than many would ever have anticipated. Holograms with which we can interact are under development (although right now they’re no bigger than a pencil eraser). In addition, 3D viewing without glasses has been researched for years. Maybe you remember the Nintendo 3DS? This technology is able to work because there are a limited number of viewing angles, as well as a small screen. The difficulties only increase as viewing positions and size of image increase. In a crowded square such as that where Marty is standing in the film, the number of potential viewing angles would be huge, and thus the 3D viewing technologies would be extremely difficult to implement. One company based in Austria, though, has developed 3D billboards which, if not viewed at the correct angle, simply appear two dimensional, an easy fix to a huge problem.

Science Fiction has allowed us to express our hopes and dreams for the future and our wildest fantasies, our proudest ideas and cleverest solutions, years or even decades before they could be possible in the real world. It’s because of people who weren’t afraid to dream and innovate that we have some of these amazing technologies today. Keep on dreaming, and may the force be with you.

Until next time,

Natalie Cummings

Recent Comments