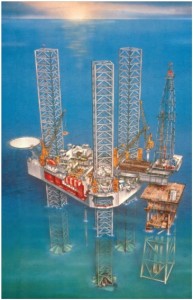

These huge awesome structures are the real producers of oil in the world. These giants can drill up to 7 miles down into the sea.

They are built at shipyards. First the base of the platform is built. The shape of this is similar to that of a triangle. There are three holes near the edges of this triangular shaped base. These holes are the places where the legs will be built in a later construction stage. These legs will rest on the ocean floors. To give extra stability to the overall structure, these legs will have a big flat surface attached at the bottom (at their feet). This flat surface is called ‘Spud Cans’. Each ‘Spud Can’ weights up to 250 tons. It covers more than fourteen hundred square feet. And on top of it is the long leg that reaches up to the platform. After the oil platform is dragged to the drilling site, powerful motors push the legs down into the sea floor with the Spud Cans attached at the bottom of the legs. Next, the entire platform comes upward so that it is can withstand hurricane waves.

Out in the open sea, the platform is a dangerous place to be – surrounded by sharks, assaulted by hurricanes and vulnerable to fire. If a fire breaks out at the platform, there is no one to run. So the life of the workers depends on how good a platform is designed. A typical oil production platform is self-sufficient in energy and water needs, housing electrical generation, water desalinators and all of the equipment necessary to process oil and gas such that it can be either delivered directly onshore by pipeline or to a floating platform or tanker loading facility, or both. They also have standby rescue and firefighting vessels. Of course, there are evacuation systems and a helipad but the task remains full of potential dangers. In short, the design of the platform is a critical element to ensure the safety of the workers – a strong oil platform is a safe oil platform.

The engineers have to decide which type of materials to use for building the legs of the platform. Steel is their first choice. During high speed winds and the strong water waves, it is better for the legs to bend than to break. Also, the legs should not buckle. This is why the legs look like a structure of steel, with powerful and strong springs in between to help with the bending incase of high-speed waves and water currents.

Each of these oil platforms can deliver millions of gallons of gas per day. The gas will then flow through the underground pipelines to reach the purification stations from where they will further reach the power stations and finally to us for our daily usage.

Works Consulted: –