PlasticPonics

Introduction

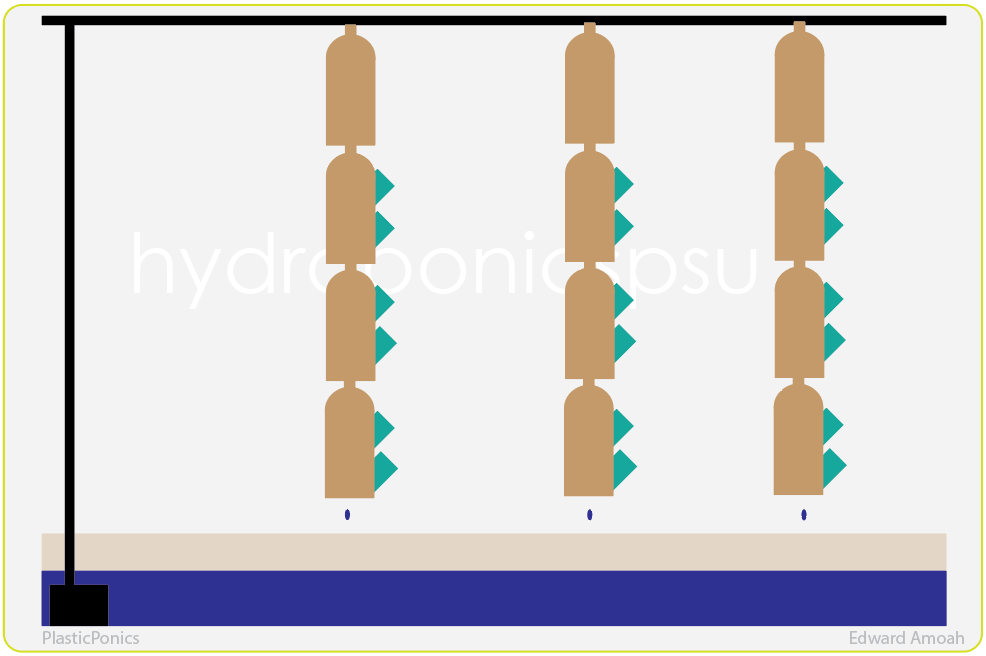

The PlasticPonics is an open-source hydroponics design developed by Edward Amoah. The design is base on vertical growing hydroponics methods. PlasticPonics are made out of plastics bottles. PlasticPonics is cheap and can be easily made by people of all financial backgrounds from anywhere in the world.

The system is made with 2L bottles containers, as the main growing containers, and 0.5L bottles as the net pods. The system is designed to be modular so the user can stack as many bottles as is needed vertically. Nutrition rich water flows up the system with the help of a submissive pump, then the nutrient solution drips down the system with gravity. As water flows through the system some of it is left in each bottle for the plants. The water in the bottle can then be pulled up for the plants using a wick. This enables the system to depend less on the pump. The level of water left in the bottles can be adjusted with the straw through which the water flows. This innovative drip down and pull up method enables the system to depend less on a pump and can even work without a pump.

This system is designed to be able to work without any electronic parts, as this may be a challenge for some people in the world. But with electronics like pumps, sensors, fans, light this can be greatly automated and effective. With electronics, the pH, temperature, and other important parameters can be monitored and checked remotely. Fans and light enable the user to adjust the environmental conditions around the system to enable optimal growth. The system can also display important notifications and readings on screen for the user, to help the user easily manage the hydroponics system.

General Overview of the Hardware System

Components List

2L Plastic Bottles: This will be the main growing container. The 2L plastic bottle will support the crops and provide them with a nutrient-rich solution.

0.5L Plastic Bottles: This will be used to make the net pods that will hold growing media and support the crops in the main growing container.

Heat Sensor: The heat sensor will be placed in the water reservoir to monitor the temperature of water in the hydroponic system. When the water is too hot the Arduino will display a message on its screen for the user to add in cold water and vice versa.

EC Sensor: The EC sensor like the heat sensor will be placed in the water reservoir to monitor the electric conductance of the water in the hydroponics system. The EC sensor measures the ability of the water to conduct electricity, which also correlates to the amount of nutrition in the water. As nutrition does increase the conductance of the water. When a low level of nutrition is detected the Arduino will display a message for the user to add in nutrients.

PH Sensor: Like the EC sensor will also be placed in the water reservoir. The sensor will monitor the pH levels of the water and notify the user via the screen if action needs to be taken.

Water Level Sensor: The water level sensor will also be placed in the water reservoir. This sensor will monitor the water levels in the button container to avoid the overflow of water. The Arduino will use information from the Water Level sensor to pump water from the water reservoir to the upper layer, which will then flow down with gravity.

Heat & humidity Sensor: This sensor will measure the air temperature and humidity around the hydroponics system. This information can be used to control external fans if some exist. This fan can then be turned on and off as the air temperature and humidity fluctuate.

Light Intensity Sensor: This sensor will monitor light intensity. This information can be used to control light systems if one exists. The control system can also notify the user to move the hydroponic system into the sun or from the sun as is needed by the system.

Control Unit: The control unit will receive data from the sensors, process the data, and display appropriate information to the user or control the water pumps, fans, light and flow valves as is needed. Raspberry Pi or an Arduino can be used for this purpose. The raspberry pi will be used for our system.

Water Pump and Flow Valve: The water pump and flow valve will be used to control the flow of water in the hydroponics system. The type of pump to use depends on how much volume of water needs to be pumped through the hydroponic system per hour and how high.

Energy Storage System: The energy storage needed depends on how much energy is needed by the pump, the valves, the Arduino, and the sensors. Power could be supplied by a socket if any is available, but this system could also be made to be able to stand alone with an external power bank or a solar system.

Control System Overview

In order to make the system easy to manage. The system is automated with the help of sensors. The Electric conductance, Ph and temperature can all be digitally checked and displayed on an LCD screen, so that the user doesn’t have to manually check it every. The pump is also automated, and it turns on and off depending on the amount of water in the top reservoir. The amount of water in the top reservoir is detected with the help of two water level sensors.

Prototype Development

A single vertical planter was developed with plastic bottles to test the design. Please find below an image and videos of the prototype.

Prototype Component List

The prototype was made with the components below;

- 2L Plastic Bottles

- 0.5L Plastic Bottles

- Arduino Microcontroller

- Arduino LCD

- Water Pump

- EC sensor

- Relay

- Water Level Sensor

- Glue gun

Assembly Instruction

Step 1 – Growing Container

Required Materials: Knife, screwdriver, glue gun, 2L and 0.5L bottles

Cut small holes into the 0.5L bottle, so that water and the roots of the crops can move freely in and out. Cut two holes about the size of the 0.5L bottles on the 2L bottle, so that the net pods can be inserted. Cut another hole at the bottom of the 2L about the size of the 2L bottle cap, so that other 2L bottles can be screwed onto it. Drill one hole into the cap of the 2L bottle and insert a straw into it. Insert the cap into the bottom of the 2L bottle and hold it in place with a glue gun. Drill at least two holes in the cap of the 0.5L bottle and insert the wick through the holes. Insert the 0.5L bottle net pods in the 2L growing container.

Step 2 – Top Reservoir

Required Materials: 2 water level sensors, glue gun, 2L bottle

Cut a hole at the bottom of the 2L bottle about the size of its cap. Make a hole in the cap, and insert a short straw. Insert the cap into the hole at the bottom of the 2L bottle and hold it in place with the glue gun. Make two slight openings a the bottom and top of the 2L bottle of the two water level sensors. We only need to know when the bottle is empty to pump water and when the bottle is full to shut down the pump. Hold the inserted sensor in place with the glue gun. Create two holes at the top of the top reservoir for the string, which will hang the vertical planter.

Step 3 – Vertical Planter

Required Materials: String

Screw the growing containers onto each other to create a vertical planter. Now screw the vertical planter onto the 2L bottle top reservoir. This top reservoir will hold the nutrient solution for the vertical planter, which will drip down through the vertical planter. With the help, string hang the vertical planter

Step 4 – Plumbing

Required Materials: Pump, tube, large bottom container.

Connect the pump to the top reservoir through a tube. Place the Large container of the rich nutrient solution under the vertical planter.

Step 5 – Electrical Interface

Required Materials: Arduino LCD, Arduino Microcontroller, Wires, Relay, 10K potentiometer, 330-ohm Resistor, soldering iron.

Solder header pins onto the Arduino LCD…

Step 6 – Programming

Required Materials: Computer, Arduino IDE, Arduino USB cable

#include <LiquidCrystal.h>

//liquid crystal

LiquidCrystal lcd(12,11,5,4,3,2);

// analog pin declaration

int WaterLevelAbovePin = A0;

int WaterLevelBelowPin = A1;

int ECPin = A2;

// Variables

int WaterAbove_val = 0;

int WaterBelow_val= 0;

float EC_val = 0;

float m = ((12.88-1.413)/(430-42)); // ms/cm

// digital pin declaration

int PumpRelayPin = 13;

void setup(){

lcd.begin(16,2);

pinMode(PumpRelayPin,OUTPUT);

}

void loop(){

digitalWrite(PumpRelayPin,HIGH);

// get analog readings

WaterAbove_val = analogRead(WaterLevelAbovePin);

EC_val = analogRead(ECPin);

WaterBelow_val = analogRead(WaterLevelBelowPin);

// pump control

if(WaterAbove_val < 50 && WaterBelow_val < 50){ //turn pump on

digitalWrite(PumpRelayPin,LOW);

while(WaterAbove_val < 50){

WaterAbove_val = analogRead(WaterLevelAbovePin);

EC_val = analogRead(ECPin);

lcd.clear();

lcd.setCursor(0,0);

lcd.print(“PUMP ON”);

lcd.setCursor(0,1);

lcd.print(“EC: “);

lcd.print(EC_val*m);

lcd.print(” “);

lcd.print(“PH: NaN”);

delay(1000);

}

digitalWrite(PumpRelayPin,HIGH);

}else{

digitalWrite(PumpRelayPin,HIGH);

EC_val = analogRead(ECPin);

lcd.clear();

lcd.setCursor(0,0);

lcd.print(“PUMP OFF”);

lcd.setCursor(0,1);

lcd.print(“EC:”);

lcd.print(EC_val*m);

lcd.print(” “);

lcd.print(“PH:NaN”);

delay(1000);

}

}