Sand Casting

|

Advancing metal casting process via 3D sand printing |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Philip King, Md Moinuddin Shuvo | Tools | Flow 3D, Solidcast, nTopology | Manufacturing | ExOne, VoxelJet |

|

Publications (as of May 2023) |

https://doi.org/10.3390/ma16020756 |

||||

Hybrid Manufacturing

|

Abrasive Flow Machining on AM thin walls and internal channels |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Sagar Jalui | Tools | Solidworks, Fusion 360, Avizo, ImageJ, Mathematica | Manufacturing | 3D Systems ProX 320 (L-PBF) |

| Publications | http://dx.doi.org/10.26153/tsw/17674 | ||||

|

Additive Manufacturing + Mass Finishing Hybrid Manufacturing System (AM+MF) |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Foxian Fan, Sagar Jalui, Kazi Shahed Safowan | Tools | Solidworks, Fusion 360, Keyence, Python | Manufacturing | 3D Systems ProX 320 (L-PBF); Arcam Q20+ |

|

Publications |

http://dx.doi.org/10.26153/tsw/17678 http://dx.doi.org/10.26153/tsw/44335 “Mass Finishing of Additively Manufactured Ti6Al4V Parts: An Investigation of Surface Finish Dependency on Build Orientation and Processing Conditions”. 2023 North American Manufacturing Research Conference (NAMRC) proceedings. Link: Available soon “Cost Analysis of Mass Fishing Additively Manufactured Metal Parts ”. 2023 Institute of Industrial and System Engineers (IISE) conference proceedings. Link: Available soon |

||||

|

Computer vision-based surface morphology evolution through feature tracking for mass finished metal-AM surfaces |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Sagar Jalui, Foxian Fan | Tools | Python (Detectron2) | Manufacturing | 3D Systems ProX 320 (L-PBF); Arcam Q20+ |

Design for Additive Manufacturing (DfAM)

| Shape Morphing Metamaterials | |||||

|

|||||

| Research Highlights | |||||

| Students | Ankit Saxena | Tools | Manufacturing | ||

|

Developing a Novel Test Artifact Design for Conformal Printing via Material Extrusion |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Sagar Jalui, Willem Groeneveld-Meijer, Jay Sim, Serah Hatch, Mychal Taylor | Tools | Slic3r | Manufacturing | Prusa MK3 |

| Publication | http://dx.doi.org/10.26153/tsw/44331 | ||||

Triply Periodic Minimal Surfaces (TPMS)

|

Multi-material and geometric gradation and fabrication of TPMS structures through Laser Powder Bed Fusion |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Jacklyn Griffis, Buket Yilmaz | Tools | nTopology | Manufacturing | 3D Systems ProX 320 (L-PBF) equip with Aerosint’s Selective Powder Deposition (SPD) recoating chambers. |

|

Design of Non-Pneumatic Tires (NPT) using TPMS |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Ankit Saxena, Avez Shaikh | Tools | nTopology, Solidworks, Ansys Mechanical | Manufacturing | 3D Systems Figure 4 Standalone |

Binder Jet Additive Manufacturing

|

Study of multimodal powder-binder interaction in binder jetting process |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | KaziSafowan Shahed, Willem Groeneveld-Meijer | Tools | Flow3D | Manufacturing | Desktop Metal ExOne Innovent+ |

Biomedical AM

|

Additive manufacturing of patient-specific high-fidelity and thickness-controlled cerebral aneurysm geometries |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Sandy Karam | Tools | 3D Sprint, SolidWorks | Manufacturing | 3D Systems Figure 4 Standalone |

|

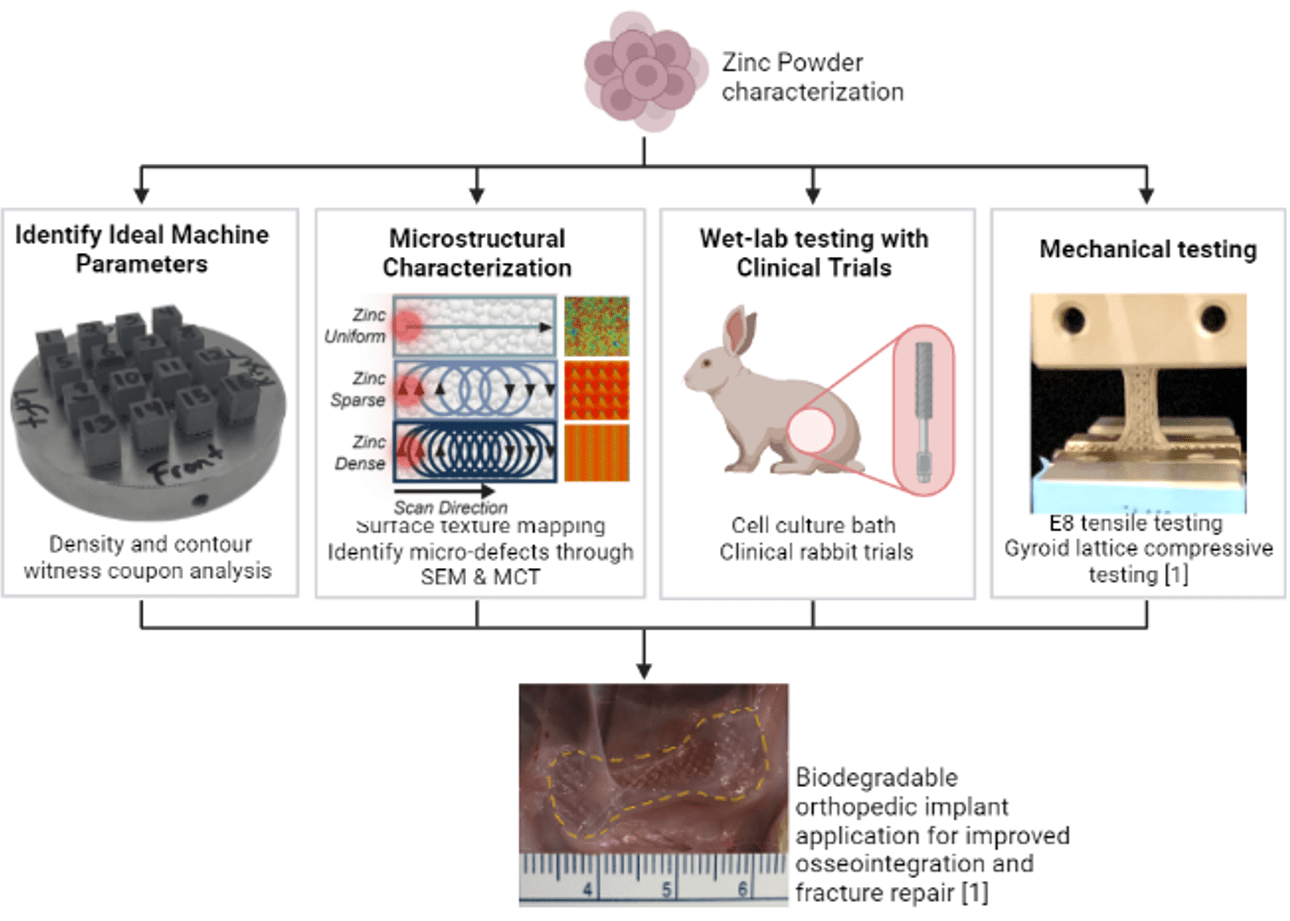

LPBF of Zinc for biodegradable orthopedic implants |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Jacklyn Griffis with Dr. Michael Hast from UPenn | Tools | nTopology, 3D Expert | Manufacturing | 3D Systems ProX 320 (L-PBF) |

|

3D Printing Using Polycaprolactone For Small Bone Fracture Fixation |

|||||

|

|||||

| Research Highlights |

|

||||

| Students | Rachel Bonfini with Dr. Michael Hast from UPenn | Tools | MSLattice, SolidWorks, PrusaSlicer | Manufacturing | Creality Ender-3 Pro |